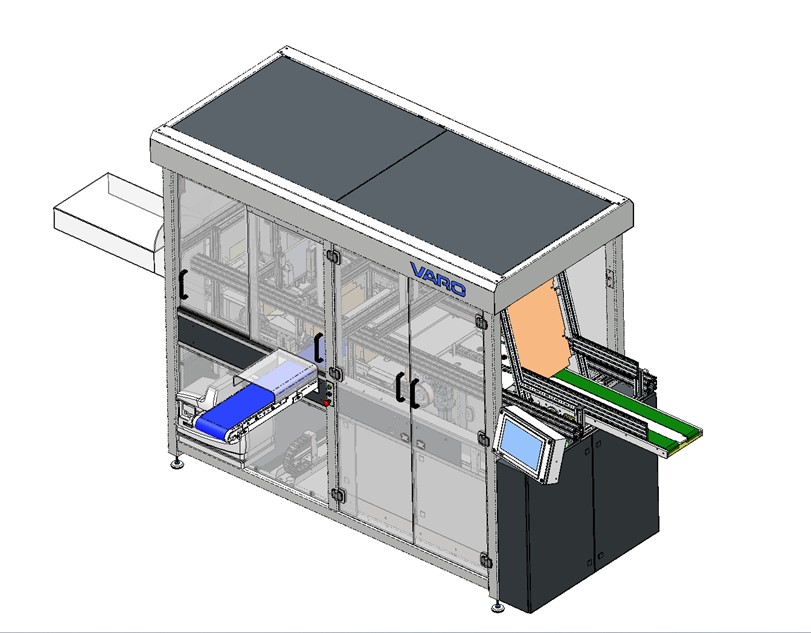

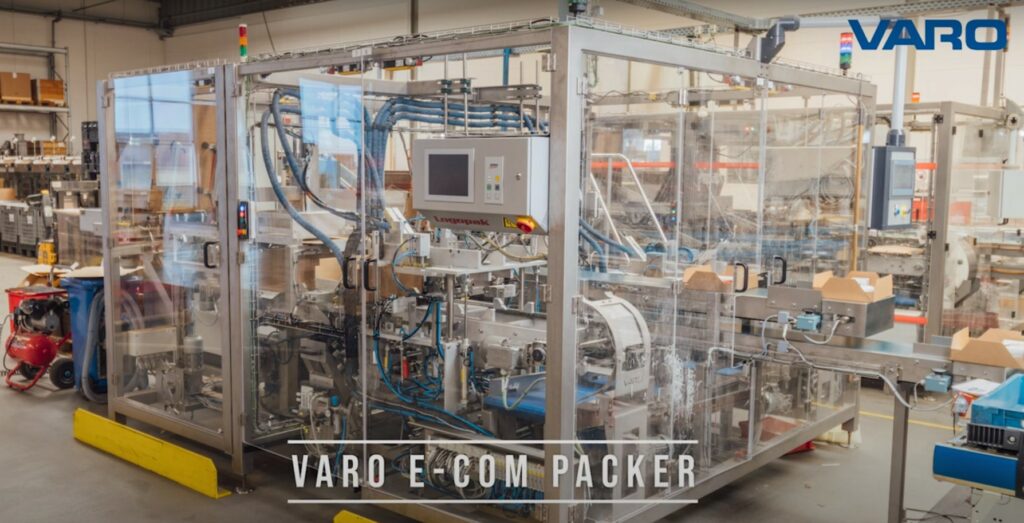

Varo E-Com Packer Gen 2 parcel packaging machine

Varo E-Com Packer Gen 2 is a packaging machine from the Danish manufacturer VARO, designed to automate the packaging process of e-commerce orders. The machine is capable of packaging various types of products, including books, cosmetics, clothes, electronics, household items and more.

What size products can be packed?

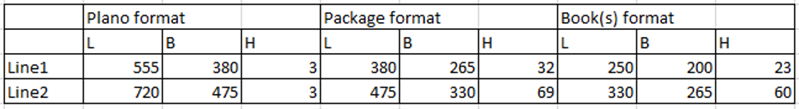

The standard VARO E-com Packer Gen 2 can pack parcels with one of the following 2 dimensions:

- 247 x 222 x 50 mm

- 330 x 265 x 56 mm

What is the Fold2Protect tray?

To further optimize the packaging process, VARO, together with the packaging specialist, invented Fold2Protect, an inner box also made of 100% corrugated cardboard that can be packed directly into the machine and packaged as part of the package. Fold2Protect is optional and is particularly suitable for packing very light or very delicate items.

Varo E-com Packer Gen 2 useful information

Varo E-com Packer Gen 2 can pack up to 900 units per hour of various products (actually approx. 720 units per hour, i.e. every 5 seconds) – using cardboard, an inexpensive and sustainable packaging material dedicated to e-commerce.

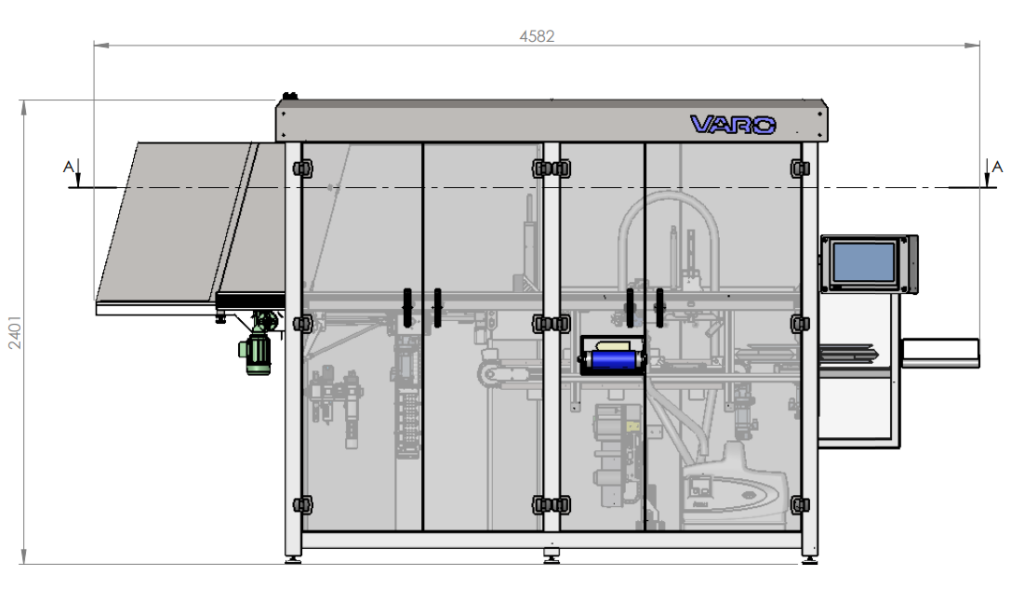

- Compact: The machine is compact and does not take up much space. It can be easily integrated with existing warehouse systems

- Eco-friendly: E-com Packer Gen 2 saves packaging material and eliminates the need for plastic such as bubble wrap

- Additional profits: Using E-com Packer Gen 2 can reduce employee costs and packaging material consumption

- Safe and cheap packing: E-com Packer Gen 2 packs completely without damaging the goods inside, reduces transportation costs by avoiding air in packages

Maszyna Varo E-Com Packer Gen 2 składa się z kilku głównych elementów:

- System podawczy: na transporterze podawczym umieszcza się produkt wykrojniku z tektury

- Urządzenie do pakowania: urządzenie do pakowania zamyka wykrojnik tekturowy z produktem

- System odbiorczy: na transporterze odbiorczym znajduje się system nakładania etykiety oraz zapakowany na kształt koperty lub płaskiego kartonu produkt

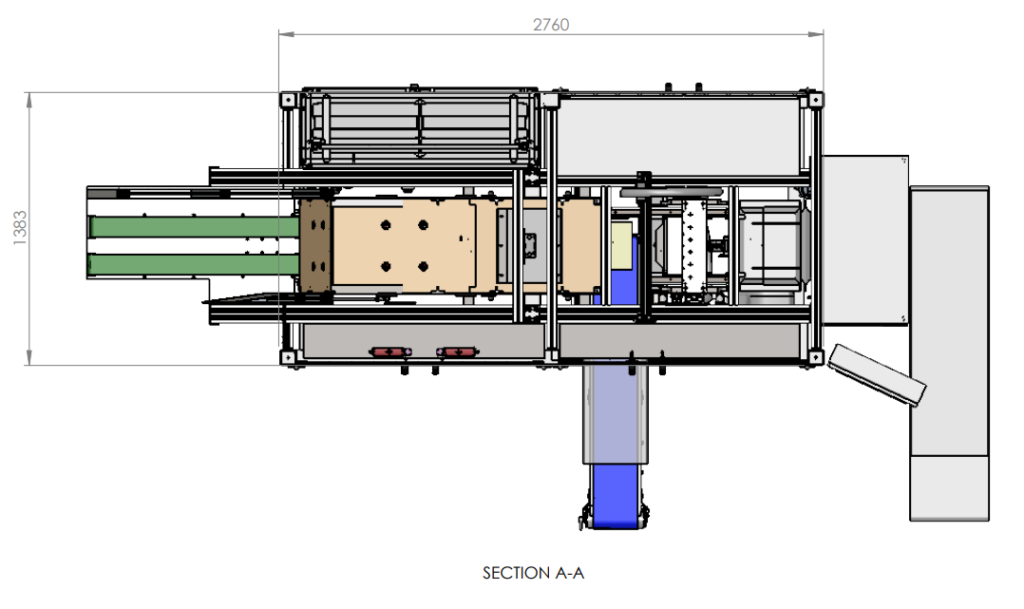

The Varo E-Com Packer Gen 2 machine consists of several main components:

- Feeding system: the cardboard die-cutting product is placed on the feed conveyor

- Packaging device: the packaging device closes the cardboard die with the product

- Receiving system: on the receiving conveyor there is a label application system and the product packed in the shape of an envelope or a flat carton

The Varo E-Com Packer Gen 2 machine offers a number of features that facilitate and automate the packaging process:

- Automatic product feeding: the machine can automatically pick up products from the feeding belt.

- Automatic product packaging: the machine can automatically pack products into various types of packaging.

- Automatic labeling: the machine can automatically apply labels to packages.

The Varo E-Com Packer Gen 2 machine is an ideal solution for e-commerce companies that want to increase the efficiency and effectiveness of the order packing process.

Advantages of the Varo E-Com Packer Gen 2:

- Automation of the packaging process: the machine can automatically pick, pack and apply labels to products.

- Increased efficiency: the machine can pack more products in less time.

- Reduced costs: the machine can reduce packaging costs (reduction of empty spaces in the shipment).

- The Varo E-Com Packer Gen 2 machine is an efficient and reliable solution for automating the packaging process of e-commerce orders. The machine offers a number of features that make the packaging process easier and faster, allowing e-commerce companies to increase efficiency and effectiveness.

Varo E-com Packer Gen 2 technical specifications

This list shows two packaging formats: A4 or A3. Others can be adapted to the customer’s needs, but the height of the products cannot exceed max. 65mm.

- How many A3 or A4 cartons fit in the cardboard warehouse? The standard magazine is 1000 mm and holds approximately 300 pieces. On request, the magazine can be extended to 2000 mm

- What is the pressure of the clamp pressing the flaps of the box? The pressure entering the machine must be 8 bar – we reduce the pressure as needed and most likely the closing zone is 6 bar. Air demand 250-400 ltr/min. The power supply is 400V

- What is the welding method? We work with hot melt glue. Bamfutura is preferred with an opening time of 16 sec. The amount of glue is on average 3 grams per package.

Is automatic product feeding possible? Yes, this is possible by simply installing a sensor at the inlet.

Additional information:

- The technical cycle time is 5 seconds per package = 720/hour.

- If smaller items are to be shipped with this device, we recommend using our internal tray (Fold2Protect). In addition to storing loose and small items, it also protects delicate products

Delivery time approximately 50 weeks from the moment the order is placed.

Quick contact: 00 48 605 318 315 and kontakt@bovmatic.pl

Stosowany